February 12, 2014

9am – 5pm

Ascott, Makati City

Fee: Php 5,500.00 / person plus 12% VAT

- Early Registration Payment: Ten-Percent (10%) Discount if PAID thirty (30) days before the training date

- Group Discount: Five-Percent (5%) on Three (3) or More Participants

[tabs slidertype=”left tabs”]

[tabcontainer]

[tabtext] About [/tabtext]

[tabtext] Course Outline [/tabtext]

[tabtext] Facilitator [/tabtext]

[tabtext] Bank Details [/tabtext]

[/tabcontainer]

[tabcontent]

[tab]

Narrative

Boilers are needed to generate a heating medium for the food, chemical, and other industrial manufacturing processes. Normally steam is needed for heating. Power boilers are a different class as this are used in the electric power generation and is out of this training module. Operating boilers efficiently saves money and the reliability of the boiler is increased saving on maintenance down time for the boiler.

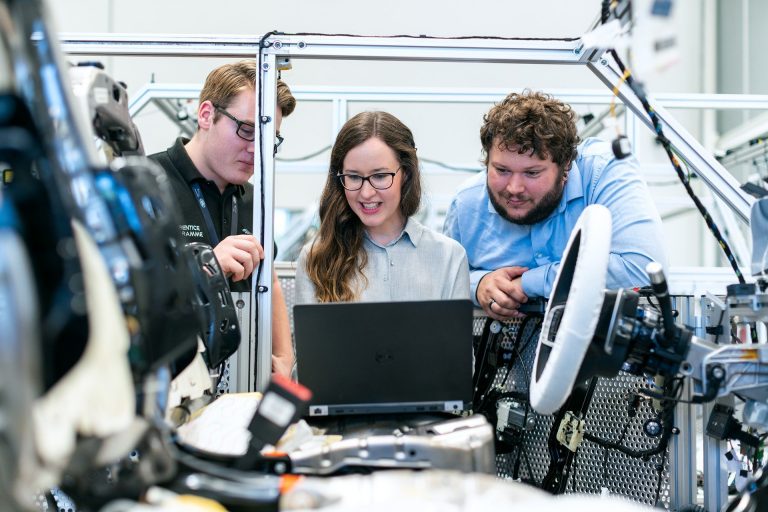

Who must attend:

- Operations supervisors

- Maintenance supervisors

- Pollution control officers

[/tab]

[tab]

Programme Outline

- Boiler operations and how to do it safely and efficiently.

- Unit Process, what process do we use the steam for, mostly heating.

- How to operate the boiler safely and efficiently?

[/tab]

[tab]

JAMES ELISEEFF

Mr Eliseeff was a graduate of BS Chemistry at the De La Salle University and an MS in Environmental Management.

He worked for Shell in the Philippines for the past 27 years from year 1982 to 30 June 2009 in varied positions in refining 17 years at the Shell Pililla Lubeoil Refinery and 10 years in Shell Oil Products Distribution Business Countrywide. My last position was the Project Manager for the completed (8.0 M USD) Chemicals remediation project at Shell Pandacan Installation for the Oil Distribution business. His job required orchestrating four (4) multinational contractors and three (3) local contractors in the demolition of surface and subsurface facilities, excavations and managing a project with numerous HSSE (Health, Safety Security, Environment) critical aspects to achieve on time, on budget and no HSSE incidents.

He has built up a cross sectional pool of knowledge / experience encompassing major aspects of the refining and Oil Products business activity in:

- HSSE

- Refinery Process Unit / Operations technologist

- Refinery Utilities and Power Plant Operations Technologist

- Project engineering and Management

- Environmental Officer for Oil Products Distribution

- Environmental Officer for the Pililla Refinery

- Regulatory Environmental Policies

- Manufacturing Management Systems (ISO 9002)

- Environmental Management System ( ISO 14001)

- Refinery Operations senior Tech A

- Normal Operations / start Ups/ Shutdowns/ emergency Procedures

- Trainor for refinery / utilities Operations staff and Terminal staff / HSS and Environment

- Trainor for Distribution staff on Health, Safety, environment for the 24 terminals country wide

- Refinery Energy Efficiency and Loss Monitoring

- Refinery Feed water treatment for Utilities, Boilers and Power Plant Technical Supervisor

[/tab]

[tab]

BANCO DE ORO (BDO)

Account Name:

Aguila Group Companies (AGC) Development Corporation

Account Number:

00 543 801 3291

Bank Address:

Alfaro-Salcedo Village Branch, PCCI Bldg., 118 Alfaro St., Salcedo Village, Makati City 1227, Philippines

Swift Code:

BNORPHMM

[/tab]

[/tabcontent]

[/tabs]

do u have a training and seminars about construction