August 8, 2013

9:00am – 5:00pm

Ascott Makati

Fee: Php 5,500.00 / person plus 12% VAT

- Early Registration Payment: Ten-Percent (10%) Discount if PAID thirty (30) days before the training date

- Group Discount: Five-Percent (5%) on Three (3) or More Participants

[tabs slidertype=”left tabs”]

[tabcontainer]

[tabtext] About [/tabtext]

[tabtext] Course Outline [/tabtext]

[tabtext] Facilitator [/tabtext]

[tabtext] Bank Details [/tabtext]

[/tabcontainer]

[tabcontent]

[tab]

Objectives of the Course:

- To provide basic knowledge of Food Microbiology, especially to food plant/factory personnel with limited microbiology background.

- To relate these basic knowledge on Microbiology in enhancing the Quality and Food Safety programs of the Company.

- To relate knowledge acquired in the control of Microbial spoilage ad Microbial contamination in the plant/factory.

Who should attend:

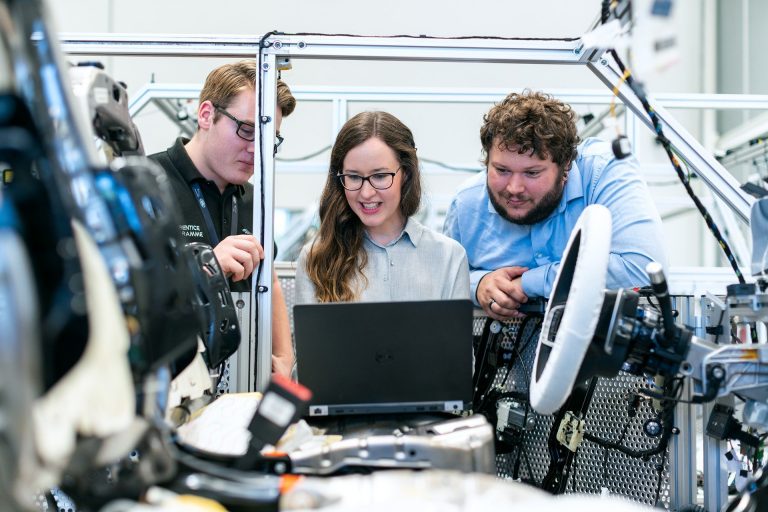

Personnels directly involved in the production and handling of food products in the food and beverage industry and allied industries like mineral water suppliers, food ingredient and food supplement manufacturers.

Personnels working in fast food industry, restaurants, catering companies, hotel restaurants, canteens and other food establishments.

For food processing or manufacturing plant, participants may come from the Production, Quality Assurance, Warehouse, Engineering and Research and Development:

- Department or Section Managers

- Supervisors

- Quality assurance analysts and QA technicians

- Product specialists and food technologists

- Production lead men or foremen

- Production operators and other production associates

- Shop floor personnel

- Maintenance and repair personnel

- Cleaning and sanitation crew

- Pest Control Officers, Pest Control Technicians and Pest Control Helpers

- Cooks and other Food Servers

- Fast food crew and restaurant food handlers

- Canteen concessionaires’ owner and crew

- Catering company owners and crew

- City and municipal sanitary personnel

Course Introduction:

Importance of Basic Food Microbiology for Food Industry Personnel

Knowledge of the basic food microbiology in combination with Good Manufacturing Practices, Pre- requisite programs can be useful in preventing food safety related problems. Intervention can take place at all levels of food manufacturing supply chain, i.e from Raw materials sourcing, reception of raw materials , tipping, mixing, processing, filling and packing, distribution and storage and despatch of finished goods.

Food factory personnel play a major role in the safe production of foods. For this reason the course was developed. Food production personnel should know how to determine when and where contamination can occur, how microorganisms survive and grow, and how to help prevent this from happening. A fundamental understanding of food microbiology would be useful in applying the practical knowledge and skills obtained from this training workshop.

Course Description:

Modular design

The five SESSIONS of this course begin with the introduction to Food Safety and related terms , then discussion will follow on the nature of micro-organisms and other hazards, move on to factors affecting microbial behaviour growth and survival, and then to the identification and control of hazards in food and food processing and preparation. Session on prevention of contamination and how to prevent them thru GMP and PRP implementation and its maintenance thru GMP rounds and audits will follow. Course validation and open discussion will conclude the workshop.

The modular design allows the course to be adapted to local needs.

Practical orientation

This course emphasises knowledge and skills that factory personnel can use to recognise unsafe food and preparation practices, and shows how this knowledge can be applied to prevent these situations.

Interactive approach

An interactive approach is essential to encourage and involve the trainees and help them acquire skills.

Evaluation

Course evaluations by the trainees and the trainers will be used as a basis for improvements.

[/tab]

[tab]

Course Outline

The course is designed for trainees with a minimum level of knowledge of microorganisms and microbiology. The target audience are production and QA supervisors, chief production operators, critical operators…and QA personnel, and Logistics/warehouse personnel.

The following sections summarise the material covered in each session

Session 1. Food Safety and Contaminants

- Definitions – The trainees are introduced to the course, food safety, GMP, PRP & Contaminants.

- Kinds and sources of Contaminants – This section describes the different kinds of Contaminants and the possible sources of these contaminants

Session 2. What is of Microbiology

- This section describes the characteristics of the main groups of microorganisms, both harmful and beneficial, and how they grow.

- This lecture explains which pathogens are infectious and where they come from, the symptoms of the diseases they cause, and some of the factors that affect infection. It does not discuss the mechanisms of infection.

- This lecture also describes toxins, the symptoms of the most important foodborne intoxications, and the factors affecting the survival of toxigenic organisms and the relative stability of toxins.

- Pathogen and Hygiene indicators.

Session 3. Factors Affecting Survival and Growth of Microorganisms

- The origins of microorganisms, and the factors affecting their survival and growth. The student will learn about the natural microflora, including pathogens, associated with raw materials, and about the related hazards. This module explains the importance of understanding microbial ecology and behaviour in the prevention of foodborne disease.

Session 4. Preservation Procedures in food

- Discussion is on the old and modern methods of Food preservation. It includes also a discussion on factors affecting Foodborne diseases.

Session 5. Prevention of Contamination

- Discussion will be on GMP and Prerequisite programs (PRP) – Implementation of GMP and prerequisite programs or the ISO/TS 2009 formerly called PAS 220

- Discussion on the pathogen and hygiene monitoring plan, corrective actions in case of pathogen infection.

Session 5. GMP audit rounds and inspection

- GMP audit- Actual GMP and inspection will be done. Presentation of findings and discussion of corrective action, responsibilities and timeline.

[/tab]

[tab]

Lauro L. Luz Jr.

Eng. Luz Jr. graduated of B.S chemical Engineering from National University.

He has worked as Quality Systems and Tech Assistance Head at the DDC Food, one of several co manufacturers for Nestle Philippines, Inc (NPI) producing the Food Service products.

Served as External Quality and Food Safety System Auditor & Consultant of RQA Group, a consulting firm based in UK.

Had conducted several factory and distribution centres audit in Asian region covering Malaysia, Vietnam & Indonesia i.e. PT Nutricia (Danone) & Sari Husada in Yogyakarta

Consultant and trainer for PT Tirta Alam Segar (PT TAS) , Kawasan Industrial Park, Bekasi , Indonesia.

Previously worked with Nestle Philippines INC (NPI) for over 32 years. He handled several positions mostly on Quality Systems Assurance, Audits and Quality Control Lab Management & Hygienist. As Corporate ISO Coordinator, he facilitated the ISO 9000 certification of Nestle Philippines factories, QA Section Head of the Microbiology Lab and member of the NPI Corporate audit Team who conducted verification audit s to NPI factories, co packers and suppliers.

[/tab]

[tab]

BANCO DE ORO (BDO)

Account Name:

Aguila Group Companies (AGC) Development Corporation

Account Number:

00 543 801 3291

Bank Address:

Alfaro-Salcedo Village Branch, PCCI Bldg., 118 Alfaro St., Salcedo Village, Makati City 1227, Philippines

Swift Code:

BNORPHMM

[/tab]

[/tabcontent]

[/tabs]

+ There are no comments

Add yours