October 9, 2013

9am – 5pm

Ascott Makati

Fee: Php 5,500.00 / person plus 12% VAT

- Early Registration Payment: Ten-Percent (10%) Discount if PAID thirty (30) days before the training date

- Group Discount: Five-Percent (5%) on Three (3) or More Participants

[tabs slidertype=”left tabs”]

[tabcontainer]

[tabtext] About [/tabtext]

[tabtext] Course Outline [/tabtext]

[tabtext] Facilitator [/tabtext]

[tabtext] Bank Details [/tabtext]

[/tabcontainer]

[tabcontent]

[tab]

Synopsis of the Course

Manufacturing processes that employ dispersions, suspensions or emulsions either as raw material or product typically experience problems related to dispensing, pumping, application, transport and stability of these colloidal mixtures. This results to production inefficiency on one hand and poor product quality on the other.

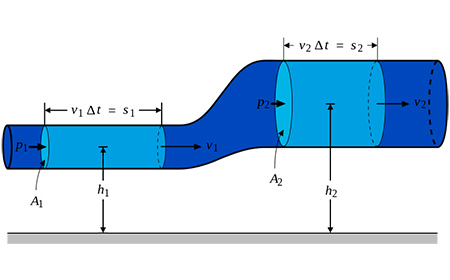

Current testing protocols in QA/QC laboratories in the industry involve the determination of viscosity, a process called viscometry. This technique involves viscosity measurement at a limited shear rate and at an uncontrolled stress value. Data obtained using this, however, does not characterize the “true” flow behavior of materials during the manufacturing steps where the material undergoes several steps under different degrees of stress. At constant temperature, unlike Newtonian fluids such as water, the viscosity values for dispersions, suspensions, emulsions and colloidal mixtures in general, are not constant, but decreases (pseudoplasticity) or increases (dilatancy) depending on the magnitude of stress applied on them. Thus, viscosity determined at rest will be different from the viscosity during actual application. If this behavior is not anticipated, problems related to dispensing, filling, transport, application and stability will result while in the process. This yields to production inefficiency.

Understanding rheology, which is the study of flow behavior of materials and performing routine rheological testing in QA/QC, hence, will improve the manufacturing process and eventually minimize if not avoid, large production losses.

This seminar will tackle various routinary methods of rheological testing applicable to food, paints, adhesives, pharmaceutical formulations, printing inks, cosmetic/personal care products, slurries, solder pastes, polymers and similar applications.

Objectives of the Course:

This seminar introduces the techniques of rheometry for routine QA/QC testing. Specifically, it aims to:

- Explain the science of rheology;

- Compare and contrast rheometry from viscometry;

- Discuss the impact of poor rheology on the efficiency of the manufacturing process and on the quality of the resulting product;

- Enumerate the different test protocols for determining material flow behavior using rotational and oscillatory techniques;

- Analyze and interpret rheological data presented in graphical form;

- Adapt an appropriate method for their application-specific need.

Who should attend:

This seminar will tackle various routinary methods of rheological testing applicable to food, paints, adhesives, pharmaceutical formulations, printing inks, cosmetics/personal care products, slurries, solder pastes, polymers and similar applications. The following are expected to attend this seminar:

- QA/QC Laboratory Managers

- QA/QC Chemists

- Process Engineers

- Supplier Quality Managers

- Product Development Specialists

- R&D Personnel

- Laboratory Analysts

[/tab]

[tab]

Course Outline:

- Session 1: Introduction to Rheology

- Definition of Rheology

- Factors affecting material flow behavior

- Classifications of Materials according to Newton and Hooke

- Different Material Flow Bahavior

- Benefits of Rheology over Viscometry

- Why Shift from Viscometry to Rheometry?: The Manufacturing Perspective

- Session 2: Routine Rheological Testing Using Rotational Technique

- How it works: Operating Principle

- Newtonian, Pseudoplasticity and Dilatancy Determination

- Protocol for Measurement of Thixotropy of Materials

- Protocol for Measurement of Yield Stress

- Protocol for Flow Behavior at varying temperatures

- Session 3: Routine Rheological Testing Using Oscillatory Technique

- How it works: Operating Principle

- Long Term Stability (Shelf Life) Determination

- Protocol for Measurement of Thixotropy of Materials

- Protocol for Measurement of Yield Stress and Flow Point

- Protocol for Measurement of Melting, Freezing, Softening and Curing Points

- Session 4: Summary and Conclusion

- The need for rheological testing in QA/QC laboratories

- Identifying important parameters for industry-specific rheological testing

- Adapting appropriate methods and techniques

[/tab]

[tab]

Rodell C. Barrientos

Mr. Rodell C. Barrientos, a licensed chemist, has a Master of Science in Chemistry degree from De La Salle University, Manila and holds two diplomas on rheological testing, one for rotational technique and another one for oscillatory technique from Vienna, Austria.

Mr. Barrientos has a wide technical experience as a trainer and consultant in the industry covering food, petrochemicals and water testing. He has also written laboratory manuals, research papers and conducted technical presentations in local and international conferences over the last five years while he was in the academe.

His expertise includes analytical method development, rheological testing of materials, rheological data analysis and interpretation, method validation and analytical separation of complex mixtures. He has attended numerous instrumentation and software trainings both local and at the international level.

Mr. Barrientos is currently connected to a Singaporean company specializing in high-end scientific instruments as an applications chemist and at the same time as an guest lecturer for industrial chemistry at Adamson University, Manila.

[/tab]

[tab]

BANCO DE ORO (BDO)

Account Name:

Aguila Group Companies (AGC) Development Corporation

Account Number:

00 543 801 3291

Bank Address:

Alfaro-Salcedo Village Branch, PCCI Bldg., 118 Alfaro St., Salcedo Village, Makati City 1227, Philippines

Swift Code:

BNORPHMM

[/tab]

[/tabcontent]

[/tabs]

+ There are no comments

Add yours